FACTORY AREA

Our production facilities are designed to support projects of every scale. the factory includes a covered production area of 3,000 m², fully equipped to handle complex steel fabrication processes. in addition, our administrative operations are housed in 320 m² of modern office space, ensuring efficient project coordination and client communication. the 5,500 m² of uncovered yard space allows for the storage, handling, and pre-assembly of large structural elements, enhancing speed and flexibility in every stage of production.

SAFETY COMES FIRST

All staff attends continus training where analyzes to the participants hazards of work.

ppe equipment is provided and its use is compulsory.

a meeting is held at the start of every shift in order to analyze the work to be done during that shift, the hazards involved and the control measures in place to manage any risk.

all factory areas have the apropriate ventilation systems to provide best working environment

for the painting of metal products there is a specific provision in an en¬closed controlled environment using the most advanced techniques covering the most stringent specifications

CONTINUOUS TRAINING FOR BEST QUALITY

All our staff is constantly trained in the latest technologies and technical specifications in the field of metal constructions so that the result produced is always at the highest level and equal to the technical specifications of each project.

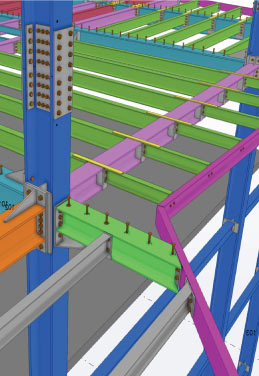

LAST EDGE TECHNOLOGY MECHANICAL EQUIPMENT

The production equipment consists of modern machinery for cutting, drilling, welding, and painting of metal components characterizing separately for ease of trans¬port, delivery and erection with significant benefits in cost, speed and quality.